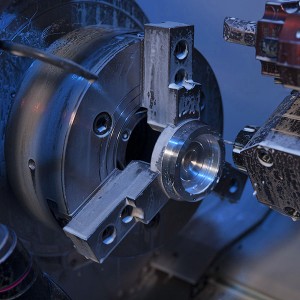

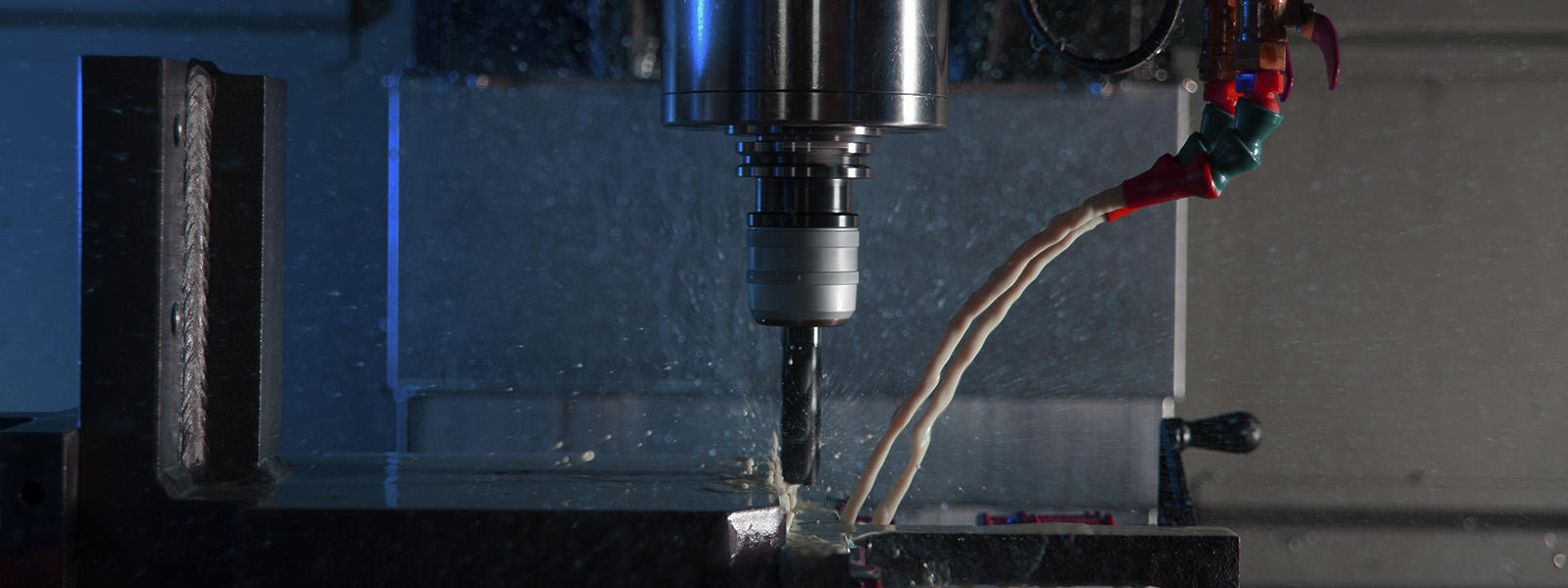

Precision CNC Machining

We Sculpt Metal & Plastic

Our machinists not only have years of experience, but also share a passion for their craft. This allows them to truly practice precision CNC machining. We regularly work with parts that are difficult to machine. We frequently take on jobs that require tight tolerances, multiple setups, or touchy materials. We like a good challenge.

Equipment

Top of the line machinery including brands like Makino and Okuma are necessary for precision cnc machining. Good equipment helps us achieve extremely tight tolerances and high efficiency. It also allows us to constantly sharpen our techniques and processes. We’ve also applied existing technology to invent a new, more efficient process utilizing both horizontally and vertically centered CNC machining, as well as live tooling integration on our CNC lathe.

Materials

We work with many different materials on a regular basis. Following is a list of those most commonly used, but we can source others if needed.

- Low Carbon Steel – 1020, 1018, A36, 12L14

- Alloy Steel – 4130, 4140PH, 4150PH, 4340, 1044, 1045

- Tool Steels – O1, A2, H13, D12, D2, P20, S7, W1,

- Stainless Steels – 303, 304, 316, 316L, 416, 420, 17-4PH

- Aluminum – 6061, 7050, 6013, 3003, 6063, MIC-6, APT5, ALCA5

- Bronze – 954, 936, 932, 360

- Titanium – Grade 5, Grade 2,

- Plastic – Delrin, Acetal, UHMW, ABS, PVC, Nylatron , G10, PEEK, Garolite(LE), Teflon, PTFE, Carbon Fiber, Nylon

Finishing

Here in West Michigan we have a vast network of suppliers. In our years of metalworking experience we’ve built relationships with the best finishing contractors in the area. Our CNC machined parts can be finished using:

- Black Oxide

- Anodization

- Hard Coat Anodization

- Hard Chrome Plating

- Electro Polishing

- Nickel Plating

Quality

We use the latest cam software and high efficiency machining practices along with advanced verification software (Vericut) to ensure impeccable quality and delivery. Learn more about our process.